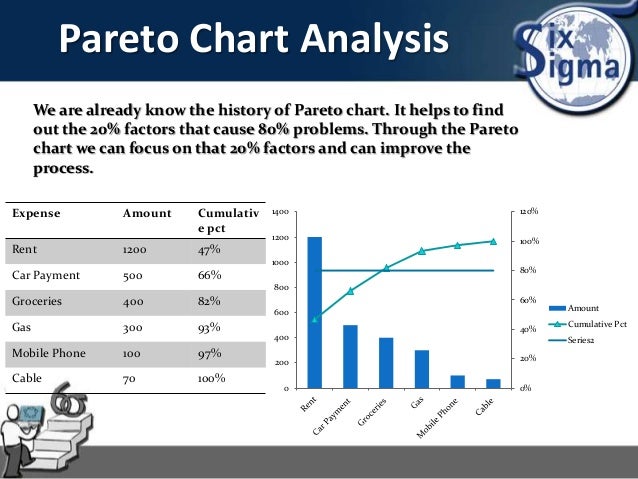

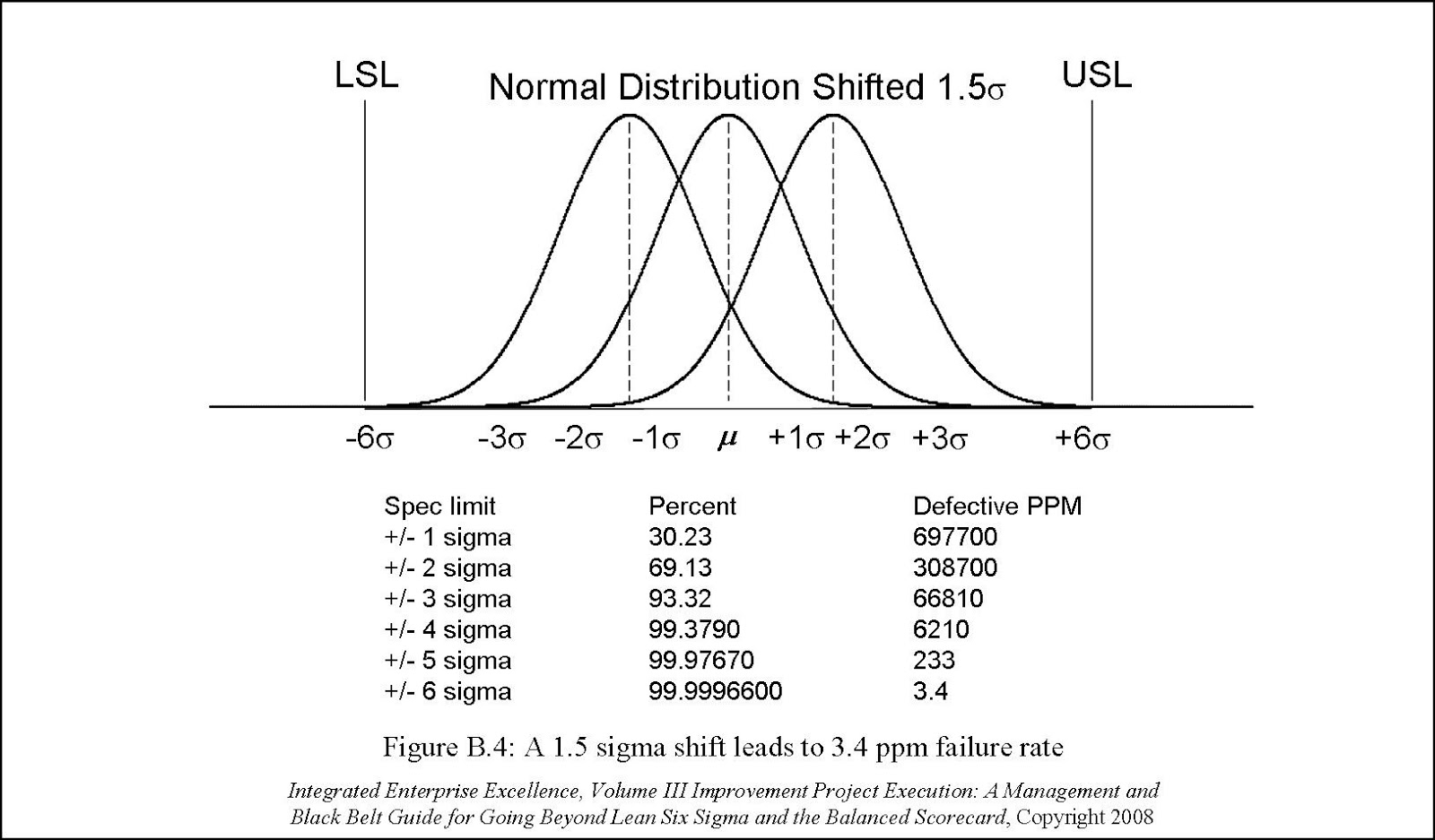

The sigma level measure is useful when you want to compare different processes or find the ones that need improvement. According to the six sigma methodology, highly capable processes. Sigma shift is used to allow for the increase in process variation over time, which occurs in real-life situations. The best possible DPMO is 0, while the DPMO will get a value of 1 million in the worst case. Here are the methodologies, roles, and certifications central to this quality management methodology. The above values comply with the six sigma industry standard, where the empirically found value of the 1.5σ mean shift is used. Six Sigma streamlines quality control to improve processes, products, or services. 3 Sigma: 66.8K errors per million (93.3 accuracy). If you want to express the amount of defect-free products created during your process, you can use the sigma levels instead of standard percentages: A six sigma level of performance has 3.4 defects per million opportunities (3.4 DPMO). The number of standard deviations between the mean of the process and the nearest specification limit describes the sigma level (does z-score ring a bell?🔔). (See our standard deviation calculator for an in-depth tour about standard deviation.)

6 sigma percentage free#

The standard deviation - sigma σ - measures the dispersion of a set of values. Statistically, 99.99966 percent of all opportunities to produce any feature of a part are expected to be free of defects, or 3.4 defects per million. Not all opportunities and defects are created equal. In the United States alone if the sigma level were between 3 and 4, there would be 50 newborn babies dropped per day and 5,000 incorrect surgical procedures per week. So what does six sigma mean, and what does it tell us? Electricity outage assuming 30 day month 720 hours 500 hours. DPMO is one metric that can be found in the six sigma methodology. How about the six sigmas? The six sigmas are a set of methods, metrics, and tools that help improve any kind of process by eliminating waste and defects, reducing variation, and ensuring quality control. i processi nell’ottica del Six Sigma, ovvero la corrente «sigma performance» del processo. When you read this below table, 4 sigmas means 4 sigma on each side Meaning the width is actually 8 sigmas. Six Sigma quality is a term generally used to indicate a process is well controlled (within process limits 3s from the center line in a control chart, and.

Better CPK 1.67 (5), this means 233 DPPM. You may have heard about the three sigmas (more of that in our empirical rule calculator). Good CPK 1.33 (4), this means 6210 DPPM, we use this, but you dont want to be here. defects \small\text defect opportunites - the number of defects opportunities per unit, so in our case, it's 5.

0 kommentar(er)

0 kommentar(er)